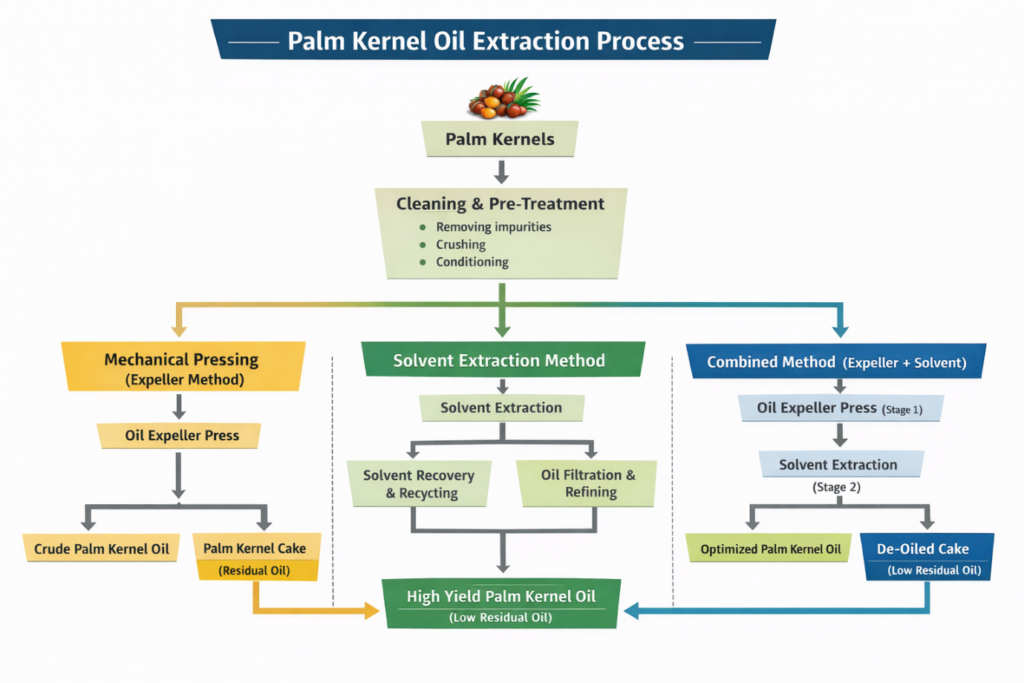

Palm kernel oil is extracted in three major ways. The choice of the method will rely on the plant capacity, the required oil recovery, the degree of automation, and the investment budget. All of the methods are adapted to fit a particular size of operation, either a small oil mill to a large industrial processing plant.

Method 1: Mechanical Pressing (Palm Kernel Oil Expeller Method)

Mechanical pressing is the most common method of palm kernel oil extraction and is applicable in small to medium-scale palm kernel oil extraction facilities. The process works on the physical force rather than the chemical separation of oil and kernels, making it easier, more reliable, and convenient to operate.

It starts with cleaning and sorting of palm kernels where vibrating screens and magnetic separators are used to eliminate stones, dust, and metal particles. Clean kernels assist in avoiding the damage of equipment and keeping the production of oil consistent. The kernels are then washed, and then crushed into small grains which exposes more surface area and enables the oil to be pressed out more easily.

The kernel material is crushed and then subjected to conditioning or cooking where it is heated carefully. The step makes the oil-bearing cells soft, decreases viscosity of oil, and enhances the overall flow of oil within the expeller. Effective conditioning is important in enhancing the yield of oil.

The conditioned content is subsequently introduced into a palm kernel oil pressor (screw press). High mechanical pressure is imposed inside the expeller where the material passes through the pressing chamber. This pressure causes the oil to be squeezed through minute holes and the solid residue to be released separately.

This method produces:

- Raw palm kernel oil which can be further refined or filtered.

- Palm kernel cake with a low quantity of residual oil.

Mechanical press is generally preferred due to the following reasons:

- Easy maintenance and simple functioning.

- Low operating and energy expenses.

- Applicability to startups and medium capacity oil mills.

Method 2: Solvent Extraction Method (High Oil Recovery)

The solvent extraction method is used in large-scale palm oil extraction facilities where the primary objective is to extract the largest quantity of oil. This technique is used mainly on palm kernel cake that has been subjected to mechanical pressing, but may also be applied as an independent process in large plants.

The palm kernel cake is introduced into a solvent extraction system in this technique, in which a food-grade solvent, usually hexane is introduced, to dissolve the remaining oil. The solvent separates the oil in the cake selectively resulting in a mixture called miscella. This miscella is then treated to separate the oil and the solvent.

The solvent is recaptured using evaporation and condensation systems, and reutilized in the process, which makes the process efficient and economical. The oil that is extracted is filtered and clarified prior to storage, and the de-oiled cake is dried and discharged to be used again.

The main results of solvent extraction are:

- Extremely high oil recovery, normally up to 95-98%

- Palm kernel cake with low residual oil.

- Stable oil quality that can be used in industries.

Due to its greater investment need and technicality this is most appropriate in:

- Massive production capacities.

- Industrial oil mills

- Maximum yield and long-term-return operations.

Method 3: Combined Expeller + Solvent Extraction Method (Most Efficient)

Combined expeller solvent extraction technique is viewed as the most effective and commercially viable approach of using palm kernel oil. It incorporates the benefits of mechanical pressing and solvent extraction to provide both maximum recovery of oil and optimal costs of operation.

This system enables palm kernels to be initially processed using palm kernel oil expeller where most of the oil is extracted by mechanical pressure. The resulting palm kernel cake which still has a remaining oil is subsequently dumped to a solvent extraction plant to extract more oil.

The combined approach minimizes the total amount of solvents used, but gives higher oil yield than either method applied separately. It also guarantees increased utilization of raw material and enhanced profitability.

This integrated approach has a number of benefits:

- Maximum oil extracted out of palm kernels.

- Less solvent consumption than total solvent extraction.

- Improved quality of oil and efficiency in the process.

- Increased overall profitability.

It is the best method to use in turnkey palm kernel oil extraction facilities and it is commonly applied by professional oil mill operators. Sudarshan Oil Expellers is a manufacturer of bespoke combined palm kernel oil extraction units, which are designed to meet the needs of a specific plant capacity, production target, and budget constraints.