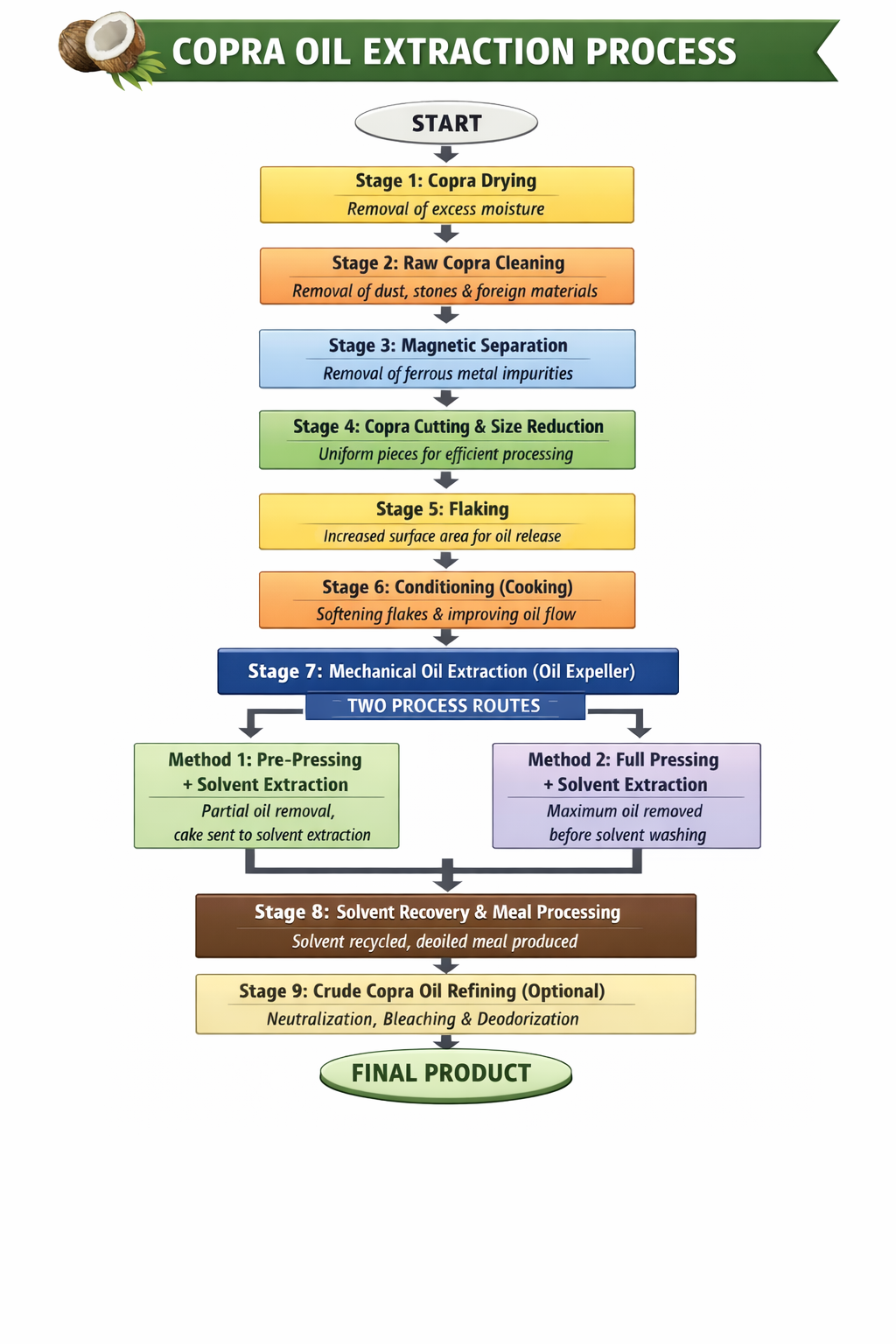

After the conditioning, oil flakes are fed into the heavy-duty oil expellers. A significant percentage of the coconut oil is squeezed out mechanically by the expellers. The pre-pressing method leaves the press cake with about 16-18% residual oil, whereas in the full pressing method, the residual oil is less, around 8-10 percent, because more than one expeller is used.

In industrial production of copra oil, the extraction of solvents is done through two major processes that include the Pre-Pressing + Solvent Extraction Method and the Full Pressing + Solvent Extraction Method. The selection of method is subject to the scale of the plant, capacity, and investment.

The most effective and commercial process that is highly adopted in production of coconut (copra) oil is the Pre-Pressing + Solvent Extraction Process. This is used in medium size to large-scale plants and new installations. In this process, the copra is pre-pressed in only one oil expeller, with about 80-85 percent of the oil being obtained by mechanical methods. The rest of the oil is obtained by solvent extraction (approximately 15-20 percent).

This process uses oil expellers to extract most of the oil in a mechanical manner and the rest of the oil is extracted using solvent extraction and this way almost all the oil is recovered without increasing the cost of running the equipment. This technique offers moderate recovery of mechanical oil and moderate load of solvents and is a cost effective option in medium scale plants.

The complete pressing process applies to large plants that have more than one oil expeller and have high throughput.

In this process, the copra is subjected to two or more successive oil expellers where most of the oil is removed in a mechanical manner prior to the solvent stage. A continuous solvent extraction system is then used to recover the remainder of oil and to achieve maximum overall oil yield and efficient utilization of installed oil expeller capacity.

The process is particularly appropriate to manufacturers that already have copra oil expellers and are interested in upgrading their plants to solvent extraction in order to increase recovery and profitability. The technique has very high mechanical oil recovery, reduces solvent usage and it is suitable to large capacity plants or upgrading of existing multi-expeller units.