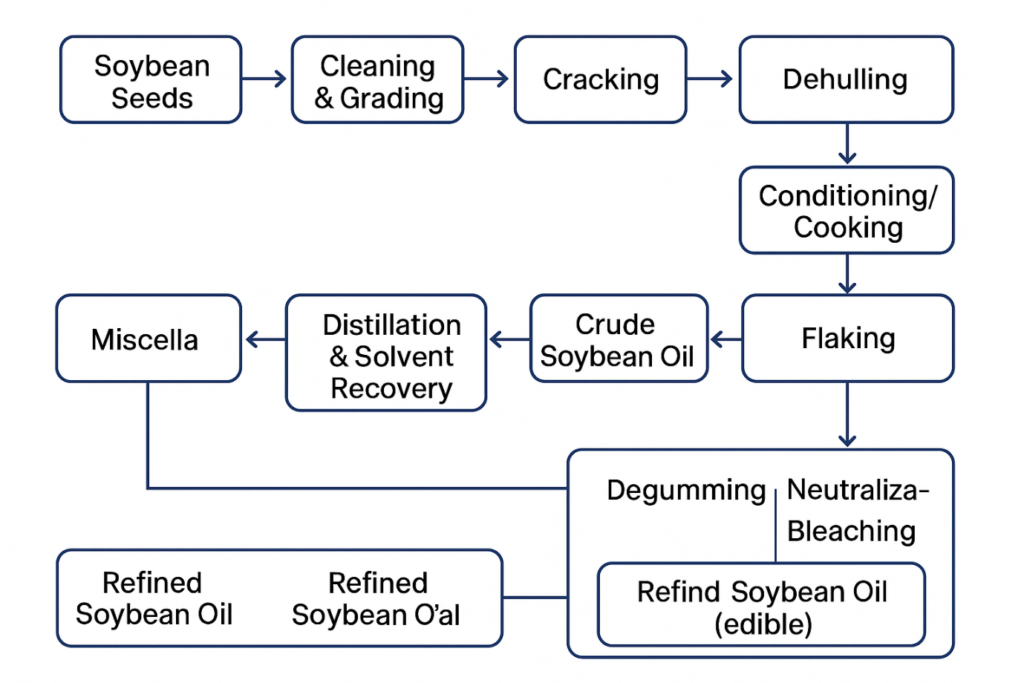

The production of refined soybean oil is characterized by many critical stages:

- Cleaning & Grading

The cleaning of soybean seeds is done with the help of vibratory cleaners, de-stoners, aspirators, and magnetic separators. Thus, the overall process consists of dust, stones, pods, split seeds, and metal particles removal. Proper cleaning prevents machinery damage and ensures uniform quality.

- Dehulling & Cracking

The hulls are removed to make oil extraction more efficient and the cracked flakes are used to enhance the protein content of the meal. The hulls that are removed can be transformed into feed fiber or biomass fuel, thus adding value and reducing waste at the same time.

- Conditioning & Flaking

The temperature and moisture of the soybeans are adjusted to soften the seeds, and thereafter the soybeans are conditioned. After this, they are flaked into thin layers that break cell structures for efficient oil extraction. This step is vital for obtaining high recovery in the solvent extraction plants.

- Mechanical Pressing

The oil extraction from soybeans done by mechanical expellers in medium-sized plants gives 60-70% of oil. The remaining cake is sent to a soybean solvent extraction plant for oil recovery maximization.

- Solvent Extraction

The large-scale processing utilizes hexane as the solvent to extract almost all of the remaining oil. The miscella is separated, distilled, and recovered, whereas the de-oiled soybean meal is desolventized and toasted yielding a protein-rich product.

- Filtration & Storage

Crude soybean oil is filtered for the removal of suspended matter, and after that, it is stored in tanks at the oil refinery.

- Refining

The processes of refining include processes like degumming, bleaching, deodorizing, and winterization, which yield food-grade refined soybean oil that is suitable for cooking, baking, and FMCG applications.