Before the mechanical processing, seeds need to be cleaned and should not have any foreign materials in them. Through the cleaning process, stones, dust, broken kernels, sticks, metal pieces, and other impurities are removed. Common devices are vibratory screen cleaners, which are used to size-separate particles, aspirators, which are used to remove light impurities using air flow, destoners, which use density to separate, and magnetic separators, which are used to separate using a magnetic process. Effective cleaning helps avoid damage to the downstream equipment, reduces the load to filters, and minimizes the contamination of the crude oil. Screens and aspirator settings are set to each type of seed and inbound impurity load operationally, and regular inspection of magnetic traps and destoner discharge is essential in order to maintain continuous operation.

Some seeds (sunflower, and some types of groundnut, cottonseed) are partially or wholly dehulled. Dehulling is the process of separating kernels and husks with the help of impact or abrasive hullers or roller shellers. Removing hulls lowers the fiber content in the cake, enhances the quality of flaking, and, in most cases, yields more oil per tonne of the kernel. But, excessive dehulling may be harmful to the kernels, and yield may be decreased; hence, machines should be programmed to protect kernel integrity. Husks collected can be useful as boiler fuel or raw material in the use of compost/fiber.

The kernel is crushed or flaked to ensure easy release of oil. Seeds are pressed into uniform flakes with roller mills or flakers, providing more oil-bearing surface area and uniform conditioning. One of the controlled parameters is flake thickness: excessively thick flakes cause oil to be retained, and excessively thin flakes cause material to pack and block conditioning systems. To create uniform flake quality across all seed types, we provide flaker installations with variable roll gap, roll surface temperature, and feed rate.

This is the controlled heating and damping of flakes to release the oil in the cellular structures. Continuous conditioners or cookers add steam and retain a certain amount of temperature and retention time based on seed, for instance, mustard and groundnut hold different conditioning recipes than soybean or cottonseed. The right conditioning de-foams proteins that adsorb oil, lowers the viscosity of oil, and assists droplet coalescence, enhancing press yield. Excessive time of cooking darkens oil and contributes to oxidative degradation, whereas inadequate time of cooking decreases extraction. To provide consistent conditioning, our designs incorporate temperature and retention time controls, steam traps, and recovery of condensate.

The stable press operation requires uniform feeding. Screw feeders, piston feeders, or the gravimetric feeders are used to feed conditioned flakes to manage throughput and minimize feed surges. Constant feed ensures that there are no pressure spikes in the screw press, there is less mechanical stress on the gearbox, and that the moisture of the cake and the residual oil are consistent. Feed systems usually have surge hoppers and level sensors to control supply when there is maintenance or fluctuation in upstream production.

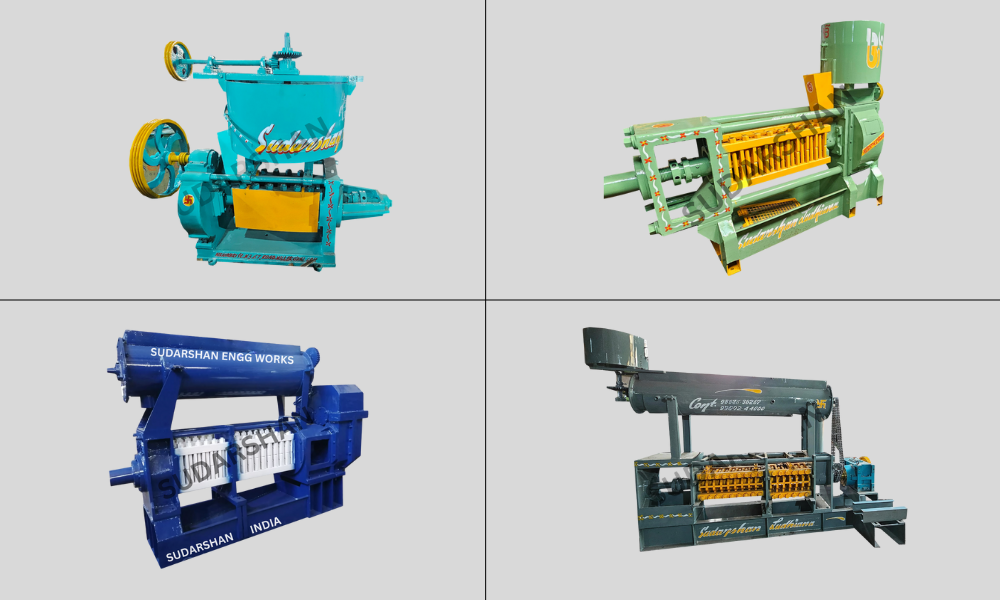

How the Expeller Operates and Equipment Specifications

An expeller consists of a rotating screw within a perforated barrel. As the flakes move through the screw, pressure rises on the progressive pitch of the screw, which causes the oil to push out through the barrel perforations, and the solids are pressed together and released as cake. The major design factors are screw profile, barrel length, pattern of perforation, gear reduction system, bearing and cooling system, and adjustable choke system to regulate back pressure. High-end expellers have interchangeable wear liners, strong gearboxes, as well as vibration and temperature monitoring.